Fast Track

3 Contact Hours. Instructional videos & quiz. No assignment

Fast Track: Value Stream Mapping 101: Healthcare Process Redesign

1.0 Contact hour ($9.99): In this course you will learn how to create a current state value stream map. This map will allow you to identify bottlenecks and barriers to workflow. By the use of meaningful metrics, we brainstorm opportunities for an improved, efficient future state.

Fast Track: A3: Problem Solving in Healthcare

3.0 Contact hours ($29.99): A3 Problem Solving is a team-based, data- and process-driven, structured method for finding root causes and implementing workable solutions in your work environment. The A3 Problem Solving method is carried out in 8 steps. Each step is recorded in a separate section on one large sheet of paper. Four sections, detailed in the four sections on the left-hand side of the page, define the Current State; the four right-hand sections define the Future or Desired State. In this course, you will learn how to execute the steps and record them in each of the sections. This problem solving method is proven to help teams make iterative improvements and solve problems permanently.

Fast Track: Lean Management: Creating a Lean Structure in the Laboratory

3.0 Contact hours ($29.99): In this course, you will learn development of leadership, operational structures, processes, people and synergistic activities that align the entire organization towards continual improvement. You will learn the methods, tools, principles of Lean and understand how to adopt these techniques to our specific laboratory environment.

Fast Track: Introduction to Lean: Tools and Concepts Specific to Laboratories

3.0 Contact hours ($29.99): This course explores Lean principles, methods, and tools specifically adapted for laboratory workflows. Participants will learn to identify and eliminate the eight forms of waste—non-value-added activities that impact efficiency. Using Lean concepts, we will examine strategies to design, refine, or eliminate processes at their root cause. By streamlining workflows, removing bottlenecks, and addressing inefficiencies, learners will gain the skills needed to optimize operations and enhance overall efficiency in the laboratory environment.

Fast Track: Adapting Toyota Principles to Laboratory Workflow

3.0 Contact hours. ($29.99): This course explores Lean tools and work rules based on the Toyota Production System. We will review key principles from The Toyota Way, focusing on eight essential operational strategies. Participants will apply these principles within a continuous improvement framework, optimizing laboratory workflows by identifying inefficiencies, streamlining operations, and fostering a culture of quality and efficiency.

Fast Track: Value Stream Mapping: Design Waste-Free Laboratory Processes

3 Contact hours. ($29.99) Value Stream Mapping (VSM) is a key Lean tool that visually represents the flow of materials and information needed to deliver a product or service to a customer. By using VSM, organizations can pinpoint inefficiencies, bottlenecks, and waste within a process, leading to enhanced operational performance and improved customer satisfaction.

Fast Track: Observation: Go, See and Ask “Why?”

3.0 Contact hours ($29.99):In this course, you will learn the "go and see" approach to observing laboratory processes to identify value-added activities and eliminate wasteful or defective steps. We will explore different types of waste, such as defects, delays, overproduction, and excess inventory, and teach you how to track a unit of work—such as a specimen, patient, or file—through its journey in the process. Once the workflow and defects are mapped, we will apply the 4 Rules of Work Design to redesign the process, transforming waste into value-added steps. By using the scientific method of problem-solving, you will optimize laboratory workflows, enhance efficiency, and improve overall performance.

Fast Track Course: Executing a Rapid Kaizen Event

3.0 Contact hours ($29.99): “Kaizen” is derived from the Japanese words “Kai” (change) and “Zen” (for the better), referring to the practice of making continuous, small improvements. A Kaizen Event is a focused, rapid improvement methodology aimed at driving productive change by enhancing a process or group of processes using Lean tools. These events are planned and executed in alignment with the organization’s strategy, goals, and objectives. The activities involved in a Kaizen Event are detailed in a project charter, which serves as a contract to guide the team’s actions and approach to change. Kaizen Events take place within a defined timeframe and involve knowledgeable, trained individuals working in an environment that encourages innovation and creativity. In this course, we will explore the steps required to create a productive continuous improvement environment using a structured Kaizen approach.

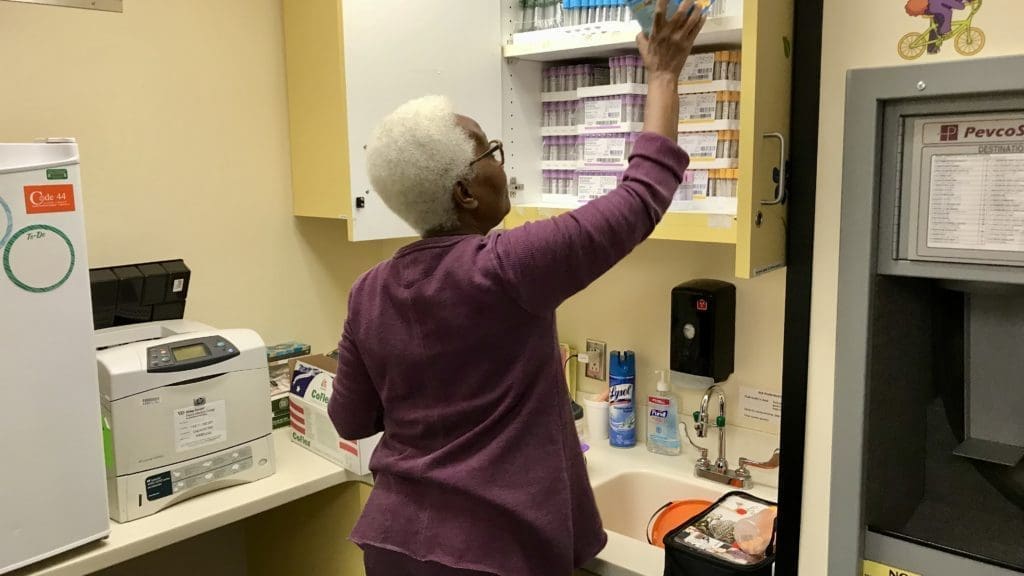

Fast Track: Conducting a 5S Event in the Laboratory

3.0 Contact hours ($29.99):In this course, you will learn the 5S Workplace Organization methodology—Sort, Set, Shine, Standardize, and Sustain—and how to apply it effectively in a laboratory setting. When implemented correctly, 5S creates a visually organized, efficient, and orderly workspace.

We will explore the key steps for planning, preparing, and executing 5S in the lab, as well as its role as a foundational Lean philosophy. By embedding 5S into daily operations, it becomes a natural part of workplace culture and sets the stage for continuous improvement initiatives.

This course emphasizes team participation and the importance of involving those who work in the area of focus. You will also learn strategies for maintaining compliance through weekly audits, follow-ups, and structured documentation. By the end of this course, you will be equipped to develop, plan, recruit, and implement 5S workplace organization in any setting—whether in your lab, organization, or home.

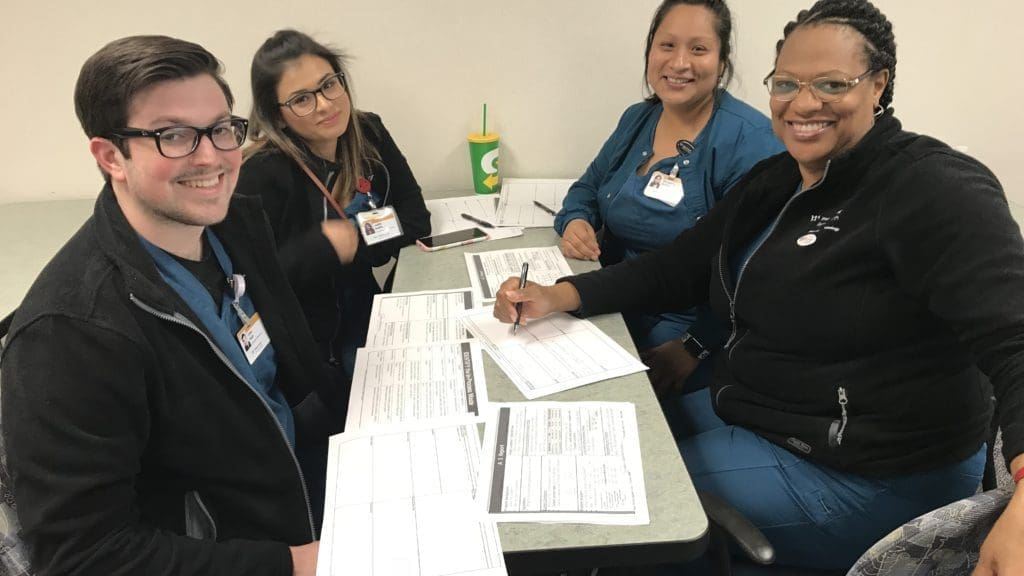

Fast Track: A3 Problem Solving in the Laboratory

3.0 Contact hours ($29.99):A3 Problem Solving is a structured, team-based approach that uses data and process analysis to identify root causes and implement effective solutions in the lab. The method is documented on a single large sheet of paper, divided into eight sections—four outlining the Current State and four defining the Future or Desired State.

In this self-paced course, you will learn how to execute each section to drive lasting problem resolution. Interactive workshops will also be available, providing opportunities to ask questions and learn from fellow lab participants.

By the end of this course, you will be able to formulate an A3, organizing all eight elements into a clear, structured diagram for your lab. You will also integrate key problem-solving tools, including process flow diagrams, the Five Whys, fishbone diagrams, and the Plan-Do-Check-Act (PDCA) cycle, to conduct a thorough A3 problem analysis.